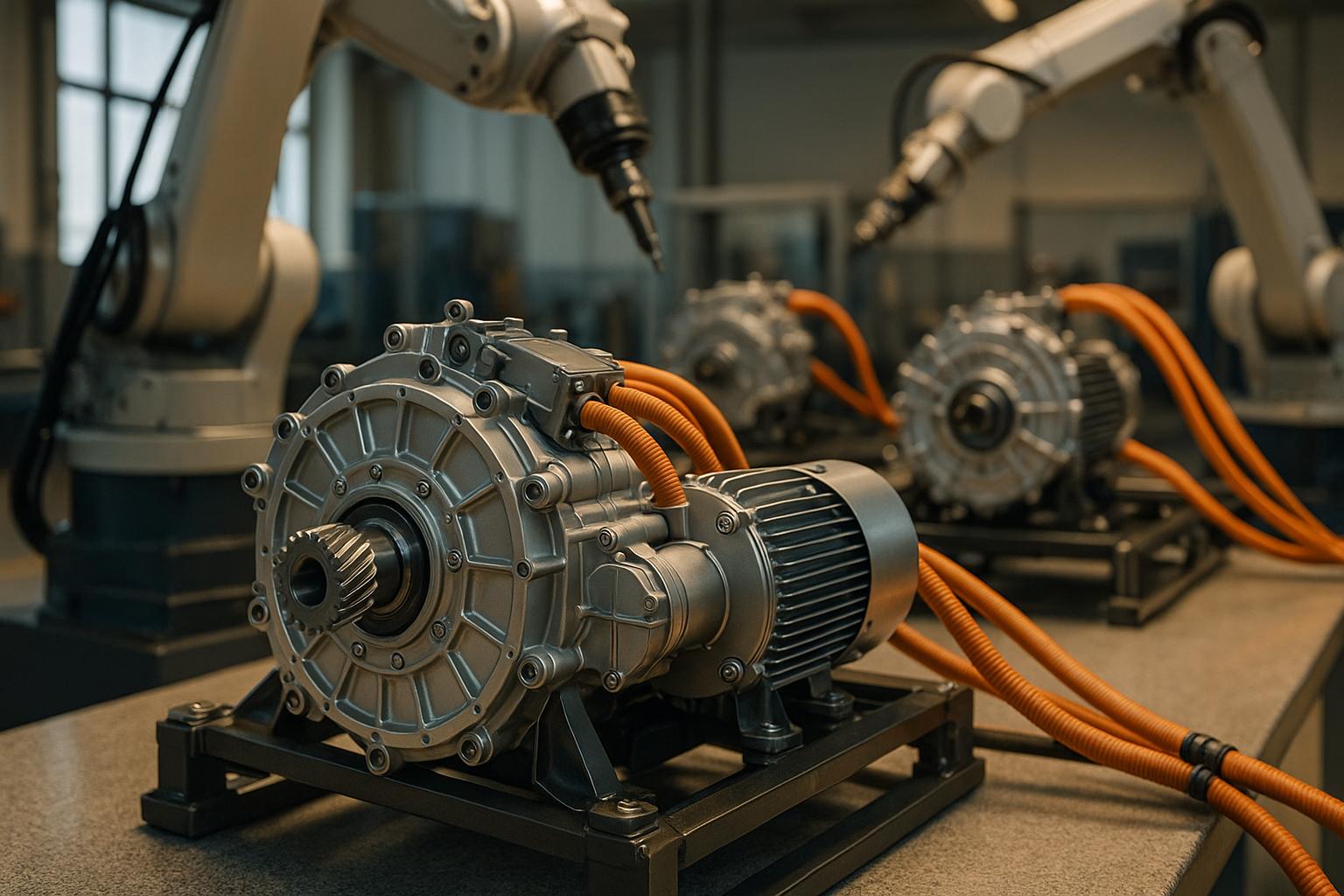

Tunisia is emerging as a key player in Africa’s electric vehicle (EV) market, leveraging its proximity to Europe, industrial clusters, and supportive government policies. The country’s drivetrain supply chain includes a mix of Chinese and European manufacturers, offering a variety of solutions to meet diverse project needs.

Key suppliers include:

- Guangzhou EPARK and Guangzhou Tengyue: Cost-effective Chinese manufacturers, though details on their production capacity and quality assurance remain unclear.

- Henan Dinis: Focuses on recreational vehicle components with customizable options.

- ABB: A global leader providing high-performance and reliable drivetrain systems with strong quality certifications.

- Bonfiglioli: Italian expertise in durable and versatile drivetrain solutions.

- Traxial: Specializes in modular, compact systems for BEVs and HEVs, offering flexibility in design and cost-efficiency.

Each supplier caters to specific needs, from budget-friendly solutions for startups to high-quality systems for industrial applications. Tunisia’s growing EV ecosystem reflects a blend of affordability and engineering expertise, making it an attractive hub for drivetrain procurement.

1. Guangzhou EPARK Electronic Technology Co., Ltd.

Guangzhou EPARK Electronic Technology Co., Ltd. is a manufacturer based in China, specializing in electronic systems for electric drivetrains. The company contributes to Tunisia’s growing electric vehicle (EV) market by supplying key components, playing a role in the development of the country’s EV ecosystem.

Product Range

Although specific details are limited, EPARK appears to focus on producing electronic control systems and components designed to integrate with EVs.

Production Scale

Operating out of Guangzhou, EPARK manufactures electronic components for both domestic use and export. However, information about their production capacity and processes remains unavailable.

Quality Assurance

There is no publicly accessible information regarding EPARK’s technical certifications or quality control measures. It is unclear whether their products meet EV-specific industry standards.

Next, we’ll take a closer look at Guangzhou Tengyue Technology Co., Ltd., another significant supplier in the electric drivetrain industry.

2. Guangzhou Tengyue Technology Co., Ltd.

Guangzhou Tengyue Technology Co., Ltd. is a China-based manufacturer specializing in electric drivetrain components. Unfortunately, there’s very little publicly available information about the company’s product lineup, production scale, or quality control processes.

Product Range

Details about the company’s electric vehicle (EV) product offerings or technical specifications are not documented in accessible sources.

Production Scale

While the company operates out of Guangzhou, there’s no available data on its production capacity or output – key factors for understanding its potential role in Tunisia’s growing EV market.

Quality Assurance

Information about its quality assurance practices, certifications, or adherence to international standards is also unavailable, making it difficult to assess its suitability for global EV component demands.

This lack of transparency highlights a recurring issue within the EV supply chain.

Next, we’ll take a look at Henan Dinis Entertainment Equipment Co., Ltd., which takes a different approach to electric drivetrain solutions.

3. Henan Dinis Entertainment Equipment Co., Ltd.

Henan Dinis Entertainment Equipment Co., Ltd., located in Henan Province, China, specializes in producing electric drivetrain components specifically designed for entertainment and recreational vehicles.

Product Range

The company focuses on creating electric motor systems tailored for amusement parks and recreational facilities. These systems are designed to prioritize low-speed performance and ensure safety, making them ideal for such applications.

Customization Options

Henan Dinis provides customized solutions, allowing clients to fine-tune system parameters to suit their specific operational requirements. This flexibility ensures their products align perfectly with diverse customer needs.

Production Scale

Operating out of its facility in Henan, the company emphasizes quality and customization in its manufacturing processes. By focusing on specialized orders for the entertainment industry, Henan Dinis has carved out a niche for itself in the electric drivetrain market, setting it apart from more generalized manufacturers.

4. ABB

While Chinese suppliers focus on niche markets, global companies like ABB bring standardized and scalable solutions to the table. ABB, a Swiss-Swedish multinational corporation, plays a key role in Tunisia’s EV market by providing advanced electric drivetrain systems. With a presence worldwide, ABB delivers electric motor and drive technologies designed for a variety of EV applications.

Product Range

ABB’s lineup of electric drive systems prioritizes precision control and energy efficiency. These systems cater to a wide range of electric vehicles, from compact cars to commercial fleets. By offering scalable and integrated solutions, ABB meets the performance demands of diverse vehicle types.

Certifications and Quality Assurance

ABB adheres to internationally recognized standards, holding ISO 9001 for quality management and ISO 14001 for environmental practices. Their components undergo rigorous testing to comply with global motor and safety standards, ensuring reliability and performance that meet the stringent requirements of the automotive industry.

Global Production and Support

With a global manufacturing network, ABB ensures the efficient production and timely delivery of high-quality drivetrain components to manufacturers in Tunisia and other regions. Their extensive support network provides technical assistance and spare parts, helping customers maintain peak operational performance.

sbb-itb-99e19e3

5. Bonfiglioli

Bonfiglioli, a well-known Italian company, brings its precision engineering expertise to the forefront as Tunisia’s EV market continues to expand.

Product Overview

Bonfiglioli provides electric drivetrain solutions designed to handle demanding conditions. While specific details about their offerings are scarce, their focus on reliability and versatility makes them an appealing choice for manufacturers looking for dependable performance across various environments.

Production and Quality

With a broad global presence, Bonfiglioli ensures its products are easily accessible worldwide. Their commitment to rigorous testing and detailed documentation highlights the reliability of their drivetrain components. This makes them a strong player in supporting Tunisia’s growing EV supply chain.

For manufacturers and investors in Tunisia, Bonfiglioli’s engineering know-how and established production network could prove to be a solid advantage when considering options for electric drivetrain components. Up next, we’ll see how their capabilities stack up against other major suppliers.

6. Traxial

As Tunisia’s electric vehicle (EV) industry grows, finding smart, adaptable solutions becomes increasingly important to meet market demands. Traxial steps in with its modular electric drive systems, designed to prioritize cost-efficiency and flexibility – two key factors for manufacturers and investors in Tunisia’s emerging EV market.

Product Range

Traxial focuses on advanced eMotor technology for both battery electric vehicles (BEVs) and hybrid electric vehicles (HEVs). Their lineup includes high-torque electric drive units (EDUs) that combine axial flux eMotors, gearbox systems, and optional inverters. These systems are highly adaptable, functioning smoothly across a wide range of battery voltages – from 400V to 900V – giving manufacturers the freedom to work with diverse power setups. Traxial’s compact axial flux motor design allows for innovative e-axle and drivetrain configurations, paving the way for more efficient and flexible EV solutions.

Customization Options

Traxial’s modular eMotor platform offers a high degree of customization. Manufacturers can mix and match multiple motors, transmission options, and integrated torque vectoring to suit various EV requirements. Their designs support co-axial, parallel offset, or direct-drive systems, and include features like transmission cooling and inverter technology for enhanced performance. With government incentives, such as full customs duty exemption on electric vehicles and a 50% reduction on hybrid car duties, the environment is ripe for adopting Traxial’s advanced EV components. This versatility positions Traxial as a strong competitor among global industry leaders.

Quality Assurance

Traxial’s integrated approach – combining an axial flux eMotor, gearbox, and optional inverter into a single, compact package – helps cut manufacturing costs and saves space. Their standardized, modular design further reduces overall production expenses, which is a significant advantage in cost-sensitive markets like Tunisia. By eliminating the need for AC cables through close motor-inverter integration, Traxial improves efficiency and minimizes electromagnetic interference. This makes their systems ideal for high-performance EVs, hybrid powertrains, and commercial vehicle fleets, aligning perfectly with Tunisia’s expanding electric mobility sector.

Supplier Comparison

When evaluating suppliers, consider factors like product variety, customization options, production capacity, and after-sales support.

Chinese suppliers such as Guangzhou EPARK and Guangzhou Tengyue are known for offering budget-friendly solutions. Their pricing and efficient delivery make them a good fit for urban mobility or lighter-duty applications, particularly for projects with tighter financial constraints.

On the other hand, established European brands like ABB and Bonfiglioli bring a different set of strengths to the table. These companies focus on drivetrain solutions designed for high-performance and industrial uses. Their emphasis on durable engineering and reliable performance makes them well-suited for commercial and heavy-duty vehicles, especially in a developing market like Tunisia.

For more specialized needs, providers like Henan Dinis cater to niche segments by offering tailored solutions. Meanwhile, Traxial delivers modular designs that strike a balance between performance and flexibility, accommodating a range of requirements.

Ultimately, the right supplier depends on your specific needs, budget, and the level of long-term support required to ensure project success and sustainable growth.

Conclusion

Tunisia’s drivetrain ecosystem offers a diverse range of options tailored to different project needs. By blending cost-efficient Chinese manufacturing with the precision and reliability of European engineering, it creates opportunities for strategic sourcing decisions.

Chinese suppliers like Guangzhou EPARK and Guangzhou Tengyue provide affordable solutions, making them ideal for startups or early-stage electric mobility projects with limited budgets. On the other hand, European companies such as ABB and Bonfiglioli bring durable engineering expertise, which is critical for commercial and heavy-duty applications. Choosing the right supplier depends on the specific demands of your project.

For manufacturers, investors, and EV developers, it’s essential to align supplier capabilities with project requirements to achieve both cost efficiency and performance. Urban mobility initiatives can benefit from the affordability of Chinese suppliers, while industrial-grade or heavy-duty applications demand the reliability of European engineering. Partnering with multiple suppliers can also enhance supply chain flexibility and keep costs competitive.

Specialized providers like Henan Dinis, known for niche applications, and Traxial, offering modular solutions, further expand the possibilities for addressing unique project needs within Tunisia’s market.

Tunisia’s ability to offer both economical and advanced drivetrain solutions underscores its growing importance in Africa’s electric mobility sector. With competitive pricing, diverse product options, and technical expertise, the country is well-positioned as a procurement hub for electric drivetrains in the region. Success hinges on careful supplier evaluation and aligning choices with specific project objectives.

FAQs

Why is Tunisia considered a promising hub for sourcing electric drivetrain components?

Tunisia is carving out a significant role in the electric vehicle (EV) industry, thanks to its prime location, skilled labor pool, and expanding manufacturing capabilities. Situated at the intersection of Europe, Africa, and the Middle East, Tunisia provides seamless access to a variety of markets, positioning itself as a strategic hub for producing and distributing EV components.

The nation is also making substantial investments in renewable energy and sustainable technologies, aligning with the global shift toward electric mobility. With a network of established suppliers known for producing high-quality drivetrain components, Tunisia is well-prepared to meet the growing demand for EVs across Africa and other regions. This unique combination of factors makes Tunisia an appealing destination for manufacturers, investors, and EV enthusiasts looking for reliable and cutting-edge drivetrain solutions.

What are the key differences between drivetrain solutions from Chinese and European suppliers in Tunisia’s EV market?

Currently, detailed comparisons between drivetrain solutions from Chinese and European suppliers in Tunisia’s EV market are hard to come by. That said, both regions tend to offer distinct advantages. Chinese suppliers are often praised for their cost-efficient production methods and ability to scale quickly. On the other hand, European companies are typically associated with cutting-edge engineering and high-quality components.

For a deeper dive, it’s worth looking into specific companies active in Tunisia to get a clearer picture of their offerings and how they’re shaping the local EV landscape.

What factors should manufacturers in Tunisia consider when selecting between modular and specialized drivetrains for their EV projects?

When choosing between modular and specialized drivetrain solutions for EV projects in Tunisia, manufacturers need to weigh factors like cost, performance, and how easily the system integrates with their designs.

Modular drivetrains stand out for their standardized design, which makes them both versatile and budget-friendly. They can help lower production costs and make scaling up production simpler. On the flip side, specialized drivetrains are custom-designed to meet specific performance needs. These systems can deliver greater efficiency or unique features tailored to the vehicle’s intended use.

The decision ultimately hinges on your priorities – whether you’re aiming for cost savings and flexibility or need a custom-built solution to achieve top-tier performance.