The cost of replacing an EV battery can be steep, but predictive maintenance offers a way to extend its lifespan and reduce expenses. By monitoring real-time data like voltage, temperature, and charging habits, predictive systems detect early signs of wear and recommend adjustments to keep your battery healthy. This approach lowers costs, improves range, and even increases resale value.

Key insights:

- Capacity loss: Predictive tools optimize charging habits (e.g., 20%-80% range) to slow degradation.

- Thermal stress: AI detects heat-related risks and adjusts cooling or charging speeds.

- Cell imbalances: Machine learning identifies and corrects uneven cell performance for better efficiency.

- Fleet benefits: For operators, these systems reduce downtime by prioritizing repairs and replacements only when needed.

For EV owners, especially in hotter regions like Africa, predictive maintenance addresses challenges like extreme temperatures and limited service options, ensuring every charge and mile counts.

Common EV Battery Problems Solved by Predictive Maintenance

Capacity Loss and Range Anxiety

Over time, EV batteries lose their capacity to hold a charge due to chemical processes like solid electrolyte interphase growth and lithium plating. While this decline happens gradually, many drivers only notice when their vehicle’s range drops significantly, sparking concerns about how far they can travel – often called range anxiety.

Predictive maintenance tackles this issue by keeping tabs on voltage curves and internal resistance in real time. When signs of degradation appear, the system can recommend changes, such as adjusting charging habits to keep the battery within a 20%-80% state of charge. Research published in Nature Energy in December 2024 revealed that dynamic charging profiles, designed to mimic real-life driving patterns, can extend lithium-ion battery life by up to 38% compared to constant-current charging methods. Similarly, data from Geotab, which analyzed 10,000 EVs, shows that sticking to the 20%-80% charging range significantly boosts battery health. Predictive systems also address related challenges, such as managing thermal stress and correcting cell imbalances.

Thermal Stress and Safety Risks

Extreme temperatures are another major threat to EV batteries. High heat – common in regions where temperatures often surpass 104°F (40°C) – accelerates electrolyte breakdown and triggers harmful chemical reactions inside battery cells. Pair this with fast charging or heavy loads, and you risk rapid performance degradation or, in worst cases, thermal runaway, which can result in fires.

Predictive maintenance systems monitor cell temperatures in fine detail, using AI-powered tools to catch unusual temperature spikes before they escalate. When thermal stress is detected, the system can adjust cooling mechanisms, charging speeds, or even the timing of charging sessions. This proactive approach not only helps prevent dangerous incidents but also mitigates heat-related capacity loss, which is especially crucial for EV owners in hotter climates.

Cell Imbalances and Hidden Faults

EV batteries rely on hundreds or even thousands of individual cells working together, but these cells don’t age equally. Variations in manufacturing, uneven charging, and temperature differences can cause some cells to degrade faster than others. These cell imbalances often go unnoticed, leading to issues like overvoltage stress in some cells while others remain underutilized. The result? A reduction in overall battery efficiency by 10-20%, even when the battery management system doesn’t flag any errors.

Predictive maintenance systems address this by using machine learning to analyze voltage data from individual cells. When irregularities are detected, advanced systems can apply active balancing during charging to level out cell performance. This ensures that no single cell is overworked or underused, boosting the battery pack’s overall health and efficiency. By focusing on the entire system, these tools help avoid unexpected failures and ensure consistent performance across all cells.

AI-Powered Battery Management Systems: The Future of EV Battery Health and Safety

How Predictive Maintenance Works for EV Batteries

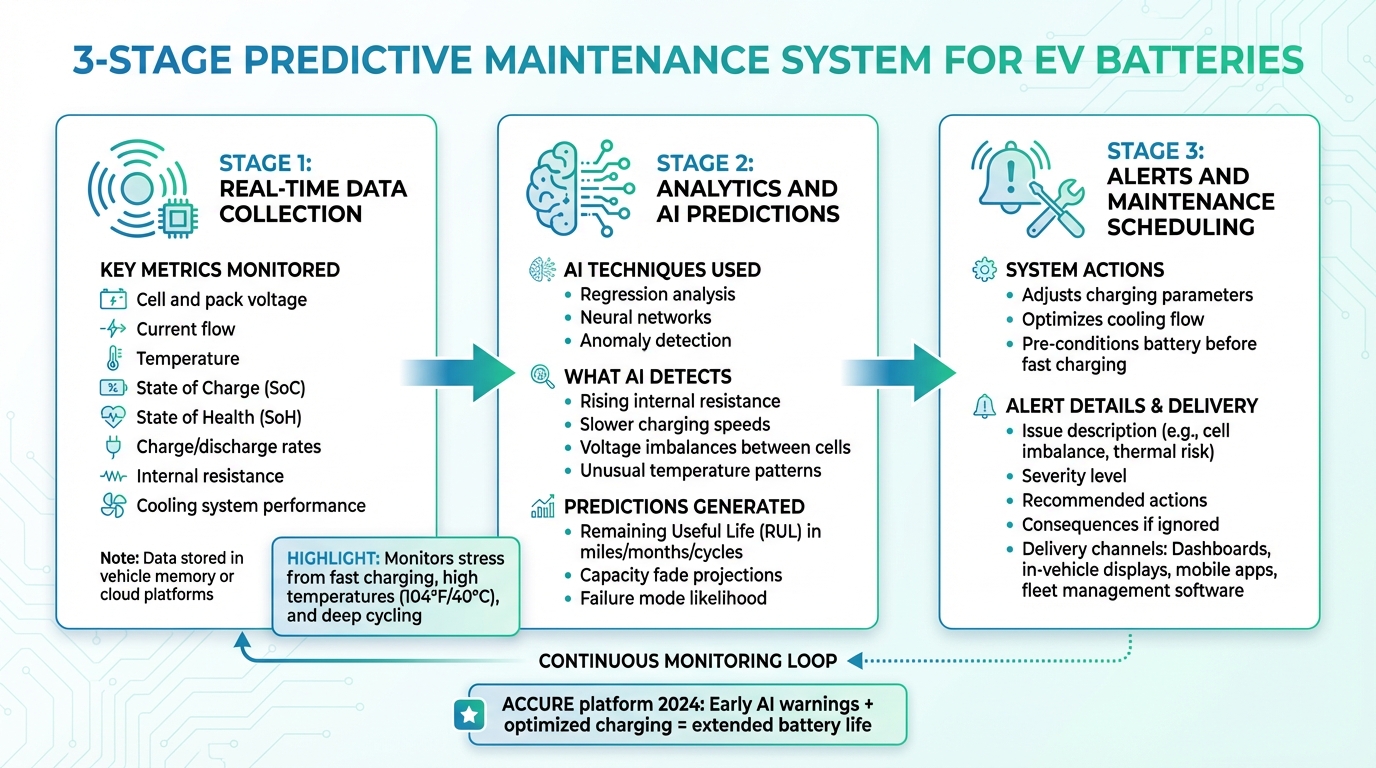

How Predictive Maintenance Works for EV Batteries: 3-Stage Process

Real-Time Data Collection

Predictive maintenance starts with the Battery Management System (BMS), which keeps a constant eye on an EV’s battery through sensors embedded in each cell and module. These sensors measure critical metrics like cell and pack voltage, current flow, and temperature. They also track the state of charge (SoC), state of health (SoH), charge/discharge rates, and the depth and frequency of charge cycles. Beyond these, the system monitors internal resistance, cooling system performance, and ambient temperature, capturing a complete picture of what the battery endures – whether it’s stress from frequent fast charging, exposure to high temperatures (around 104°F/40°C), or deep cycling.

This data is recorded at precise intervals and stored either in the vehicle’s memory or uploaded to cloud platforms for trend analysis and fleet-wide comparisons. The BMS and backend systems work together to filter out noise, correct sensor inaccuracies, and synchronize measurements across all cells. These real-time insights allow for proactive care, directly impacting the battery’s lifespan. Preprocessing this data enables calculations of advanced indicators like average cell voltage, SoC differences between cells, temperature variations across the pack, and resistance growth over time. The system also tags operating conditions – such as city versus highway driving, climate exposure, and charging habits – to differentiate normal wear from potential misuse.

Analytics and AI Predictions

Once the data is cleaned and synchronized, advanced AI models step in to forecast battery performance. Using machine learning techniques – like regression, neural networks, and anomaly detection – the system predicts battery health and its remaining useful life (RUL). The AI continuously compares the battery’s evolving metrics to established degradation patterns. Small but meaningful changes, such as rising internal resistance, slower charging speeds, or persistent voltage imbalances between cells, can signal emerging problems. At the pack level, anomaly detection identifies modules with unusual temperature or voltage behavior, enabling early intervention before range loss becomes noticeable.

The results of these analyses include detailed predictions like RUL (expressed in miles, months, or cycles), capacity fade projections, and the likelihood of specific failure modes. This allows for targeted actions to address issues before they escalate.

Alerts and Maintenance Scheduling

Predictive maintenance doesn’t just forecast problems – it actively helps prevent them by providing actionable recommendations to the BMS and vehicle systems. When the analytics detect conditions that could accelerate degradation, the system adjusts parameters like charging and cooling to mitigate risks. For instance, thermal models might pre-condition the battery before fast charging or optimize coolant flow to protect cells.

These insights are shared through dashboards, in-vehicle displays, fleet management software, or mobile apps. Alerts typically include details about the issue (e.g., abnormal cell imbalance or thermal risk), its severity, recommended actions (like scheduling service within a certain mileage), and the potential consequences if ignored – such as reduced range or RUL. For fleet operators, aggregated data across vehicles helps prioritize maintenance tasks and cut down on unexpected downtime.

In 2024, ACCURE’s predictive analytics platform for EV fleets showcased how effective these strategies can be. The platform provided early AI-driven warnings, optimized charging schedules, and long-term battery life predictions. For individual drivers, these systems can sync with service networks to suggest appointment windows before critical thresholds are reached, minimizing the chance of roadside breakdowns.

sbb-itb-99e19e3

Benefits of Predictive Maintenance for EV Batteries

Predictive maintenance, powered by real-time data and AI-driven insights, offers a range of benefits for maintaining EV batteries effectively.

Smarter Charging Practices

With the help of real-time AI analysis, predictive maintenance transforms complex battery data into straightforward charging recommendations. By monitoring sensor data like voltage curves and temperature patterns, these systems adjust charging parameters dynamically to maintain an ideal charge range, reducing wear and tear on the battery. For EV owners in regions like Africa – where grid reliability can vary and high temperatures are common – this guidance is particularly useful. For instance, the system might suggest charging during cooler times of the day or slowing the charging rate when thermal sensors detect potential stress. These adjustments help avoid cell imbalances and extend the battery’s lifespan, ensuring dependable performance.

Targeted Repairs and Refurbishment

Instead of replacing an entire battery pack when issues arise, predictive maintenance pinpoints specific cells or modules that need attention. Advanced machine learning algorithms can detect subtle changes in resistance or voltage long before they escalate into larger problems. For fleet operators, this means more precise repairs, minimizing both downtime and costs. Individual EV owners benefit too – actions like balancing cells or replacing a single module can make repairs more affordable. These targeted approaches not only cut expenses but also improve the overall reliability and longevity of the vehicle.

Better Resale Value and Buyer Confidence

Predictive systems generate detailed battery health reports, which can significantly boost the resale value of an EV. These reports provide clear, verified data on the battery’s condition and degradation history, addressing common concerns about battery longevity. This transparency is especially valuable in marketplaces like EV24.africa, where buyers across 54 African countries depend on trustworthy information when purchasing used EVs. A certified battery health report builds confidence in the transaction, making it easier for sellers to attract buyers and for the second-hand EV market to thrive.

Conclusion

Predictive maintenance is transforming EV battery care by replacing guesswork with proactive strategies. Using real-time data, it enables timely adjustments in charging and usage, helping to prevent long-term damage to batteries. By optimizing charging patterns, it slows down capacity loss, while continuous monitoring and maintaining cell balance reduce the risk of serious thermal issues and rapid wear.

These advancements aren’t just technical – they make a real financial difference. This approach cuts down on emergency repairs, delays the need for expensive battery replacements, and lowers electricity costs per mile for drivers in the U.S..

The benefits extend beyond the technical realm, especially in emerging markets. In Africa, predictive maintenance fosters trust by providing transparent battery health reports, ensuring fair pricing and dependable warranties. Access to objective health data also alleviates range anxiety and challenges the perception that EV batteries degrade too quickly.

Platforms like EV24.africa are leveraging these advancements to build confidence among buyers. By offering listings with verified battery health metrics – such as state of health, estimated range, and remaining lifespan – the platform enhances trust across all 54 African countries it serves. As AI and analytics continue to adapt to African driving habits and climate conditions, predictions become even more precise and tailored to local needs. This creates a feedback loop where better data drives more effective maintenance, longer battery life, and smarter EV investments.

EV battery life isn’t set in stone – it’s something you can actively manage and extend. For African buyers, choosing vehicles with predictive monitoring means lower lifetime costs, reduced risks, and higher resale value. This makes early EV adoption not just a sustainable choice but also a financially savvy one. Predictive maintenance is proving to be a key factor in maximizing the value of EVs in both African and U.S. markets.

FAQs

How can predictive maintenance help extend the life of an EV battery?

Predictive maintenance plays a key role in keeping your EV battery in top shape by spotting potential issues before they escalate. Using advanced monitoring tools, it keeps a close eye on battery performance, flags irregularities, and suggests timely actions to prevent serious damage.

By fine-tuning charging cycles and addressing small problems early, predictive maintenance helps ease unnecessary stress on the battery. This approach not only boosts efficiency but also helps extend the lifespan of your electric vehicle’s battery.

How does AI help prevent overheating in EV batteries?

AI is a game-changer when it comes to keeping EV batteries at the right temperature. By analyzing real-time data, it can predict and prevent overheating before it becomes a problem. It fine-tunes cooling systems and adjusts performance settings, ensuring the battery stays within a safe temperature range.

This proactive approach doesn’t just improve safety – it also reduces wear and tear on the battery, helping it last longer. In turn, this makes electric vehicles more dependable and efficient for everyday use.

How does predictive maintenance address cell imbalances in EV batteries?

Predictive maintenance is crucial for spotting and fixing cell imbalances in EV batteries. With advanced monitoring systems and data analysis, it identifies irregularities in voltage, temperature, or capacity across battery cells before they escalate into major problems.

Catching these issues early can significantly extend the battery’s lifespan while maintaining consistent performance and efficiency in your electric vehicle. This forward-thinking method helps avoid expensive repairs and minimizes downtime, ensuring your EV stays on the road without interruptions.