Africa’s electric vehicle (EV) market is booming, but the continent depends heavily on imported vehicles and parts. Here’s why:

- Limited local production: Most African countries lack the infrastructure to manufacture EV components like batteries and motors.

- Global supply chains dominate: Companies like BYD and Tesla provide affordable, mass-produced EVs and parts that local manufacturers can’t match.

- Policies favor imports: Many governments reduce import duties to make EVs affordable, but this discourages local manufacturing.

- Infrastructure challenges: Poor transport networks, unreliable electricity, and customs delays make local production costly and inefficient.

- Skills gap: A shortage of technical expertise hampers the development of EV manufacturing industries.

Despite these challenges, countries like Ethiopia, Kenya, and Ghana are taking steps to encourage local assembly and production by leveraging their natural resources, offering tax incentives, and forming regional partnerships. Africa’s future in EV manufacturing depends on addressing these barriers while balancing the benefits of imports.

Chinese Tech Driving EV Boom Africa Can’t Afford to Miss

Why Africa Depends on Imported EV Parts

Africa’s reliance on imported electric vehicle (EV) parts is shaped by several challenges that have influenced the development of its EV industry. These factors highlight why importing components is often more practical than producing them locally, creating a dependency that continues to define the continent’s EV landscape.

Limited Local Manufacturing Infrastructure

One of the biggest hurdles to local EV part production is the lack of manufacturing facilities. Most African countries simply don’t have the infrastructure needed to produce key components like lithium-ion batteries, electric motors, or advanced control systems. Building such facilities requires significant upfront investment, years of research and development, and technical expertise that is currently in short supply. As a result, even companies involved in assembling EVs on the continent often rely on imported parts to complete their vehicles.

Dominance of Global Supply Chains

Global supply chains, especially those led by Chinese manufacturers such as BYD, Leapmotor, Dongfeng, and Geely, dominate Africa’s EV market. These companies have decades of experience, large-scale production capabilities, and efficient logistics networks, allowing them to deliver EVs and components at a scale and cost that local producers struggle to match. Platforms like EV24.africa highlight how these imports maintain a strong presence, making it difficult for emerging local players to compete.

Policies That Favor Imports

Government policies in many African countries also play a role in the reliance on imports. By reducing import duties and providing fiscal incentives, these policies encourage the adoption of EVs but do little to promote local manufacturing. The table below shows how varying policies impact EV imports and pricing across different countries:

| Country | Import Duty | Policy Impact | Price Effect |

|---|---|---|---|

| Rwanda | 0% | High EV adoption; limited local production incentive | GEELY PANDA MINI: $5,880 |

| Ghana | 0% (8 years) | Attracted assembly investments | Stimulated foreign investment |

| Kenya | 0% + VAT exemption | 5× increase in EV registrations (2023) | Significant boost in adoption |

| Uganda | 25% (changed in 2024) | Shift from earlier incentives; higher costs | Notable price increase |

For example, Rwanda and Kenya have significantly reduced import duties and provided tax breaks, which have driven EV adoption but discouraged the development of local manufacturing. These short-term measures focus on market growth rather than building long-term industrial capacity within the region.

The Bigger Picture: Import-Driven Growth

Industry forecasts predict a 56% compound annual growth rate (CAGR) for Africa’s EV market between 2025 and 2030, fueled largely by imports and supportive government policies. While this rapid growth is encouraging, it underscores the continent’s dependence on externally sourced components and vehicles – a dynamic that continues to shape Africa’s EV industry. This dependency will be explored further in the next section.

Barriers to Building Local EV Supply Chains

Africa’s dependence on imports is heavily influenced by challenges in developing local supply chains. These hurdles go beyond simple market preferences, making it difficult to establish a strong domestic production base for EV components.

Infrastructure Problems and Logistics Issues

Africa’s infrastructure struggles create major roadblocks for manufacturing EV parts locally. Poor transportation networks and unreliable rail systems make it both expensive and time-consuming to move raw materials and finished goods.

Electricity is another critical issue. Frequent power outages and voltage inconsistencies disrupt production processes that require precision and can even damage equipment.

Ports and customs add another layer of difficulty. Inefficient port operations, lengthy customs procedures, and limited cargo-handling capabilities drive up shipping costs. On top of that, a shortage of specialized storage facilities – like temperature-controlled warehouses for sensitive parts – further complicates logistics.

Currency Changes and Price Problems

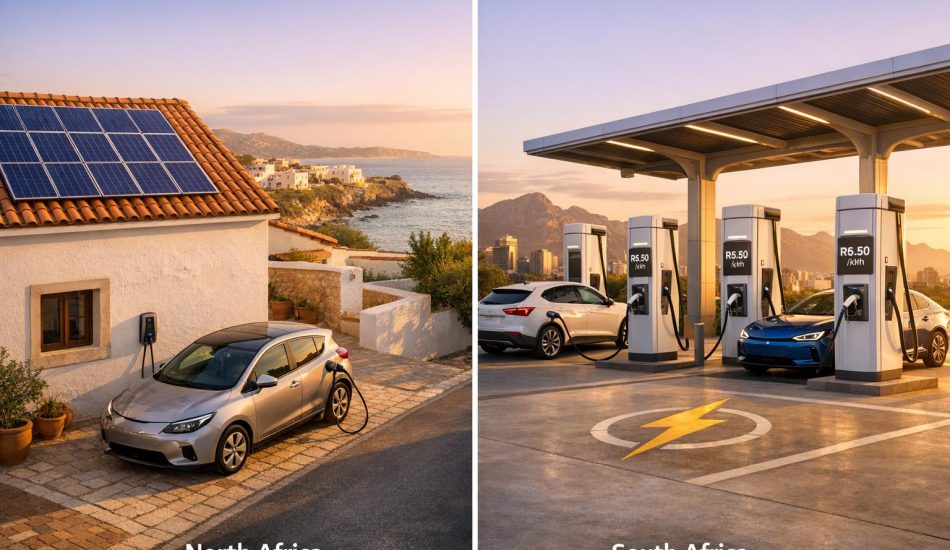

Financial instability is another challenge. Exchange rate fluctuations and sudden policy changes create uncertainty for local supply chain operations. For example, Uganda’s 2024 duty hike significantly increased EV prices, while South Africa’s 25% duty and luxury tax make EVs less competitive. On a global scale, supply chain disruptions only add to these pressures, forcing manufacturers to navigate rising costs and potential delays. This financial unpredictability makes it harder for businesses to invest in local production.

Skills Gap and Technology Shortages

A lack of skilled labor is a significant barrier to producing EV components in Africa. Manufacturing advanced parts like batteries and electric motors requires specialized knowledge – expertise that is often scarce. Without a skilled workforce, efforts to create and maintain local supply chains remain a steep uphill battle.

sbb-itb-99e19e3

Solutions for Local EV Production

Africa is making strides toward reducing its reliance on imported electric vehicles (EVs) by fostering local production. Despite facing significant challenges, the continent has opportunities to develop its manufacturing capabilities through strategic investments, resource management, and creative partnerships.

Government Programs and Investment Plans

Governments across Africa are rolling out initiatives to attract EV manufacturers and establish policies that support local production. Morocco is a standout example, having successfully drawn in major global battery and EV component manufacturers. This approach has strengthened the local supply chain and reduced the country’s dependence on imports.

In Ethiopia, the government’s decision to ban internal combustion vehicles by 2024 sparked a surge in EV sales, which exceeded 60% by early 2025. This rapid transition highlights how strong government policies can drive demand for local assembly and maintenance capabilities.

Similarly, Kenya has introduced financial incentives that have encouraged significant local investments. Other countries, including Ghana, Rwanda, and Ethiopia, are using zero-duty incentives and government-backed plans to boost EV adoption. These policies are motivating manufacturers to commit to local assembly, creating more opportunities for domestic production.

Beyond policy measures, Africa’s natural resources provide a critical advantage in building a sustainable EV industry.

Leveraging Africa’s Natural Resources

Africa is home to vast reserves of key minerals essential for EV batteries, such as cobalt from the Democratic Republic of Congo and lithium from Zimbabwe and Namibia. These resources are crucial for establishing a self-reliant EV supply chain.

Some countries are taking bold steps to ensure these resources add value locally. For example, Zimbabwe has banned the export of unprocessed lithium. This move encourages investment in local refining and battery production, creating jobs and retaining more economic benefits within the country.

By focusing on refining and battery manufacturing, African nations can move up the value chain. Instead of exporting raw materials for processing overseas, they can develop domestic capabilities for producing finished components. This approach not only reduces reliance on imports but also creates higher-paying jobs in advanced manufacturing sectors.

Local Startups and Regional Partnerships

African entrepreneurs and regional collaborations are playing a key role in tailoring EV solutions to local needs. In Kenya, Opibus (now Roam) has localized electric motorcycle assembly and retrofitting services. The company converts traditional combustion vehicles into electric ones and assembles electric motorcycles, proving that homegrown solutions can effectively meet market demands.

In Nigeria, companies like MAX and Metro Africa Xpress are advancing local EV platforms and assembly lines. These startups focus on practical, cost-effective solutions designed specifically for African markets.

Battery-swapping and electric motorcycle solutions are gaining popularity in countries like Kenya, Nigeria, Benin, Togo, and Rwanda. These approaches provide affordable and scalable EV options without requiring extensive charging infrastructure.

Regional collaboration is amplifying these efforts. Organizations like the African Association for E-Mobility are fostering knowledge exchange and cross-border joint ventures, while the African Continental Free Trade Area (AfCFTA) facilitates the movement of goods, services, and expertise. By pooling resources and harmonizing standards, these partnerships are helping to build shared infrastructure and economies of scale, making local EV production more viable.

When combined with supportive government policies and strategic use of natural resources, these efforts lay the groundwork for reducing Africa’s dependence on imported EV components. This sets the stage for broader policies that can accelerate the continent’s transition to locally produced electric vehicles.

Policy Recommendations to Reduce Import Dependency

Addressing the challenges of local production, these policy recommendations lay out practical steps to reduce Africa’s reliance on imports in the electric vehicle (EV) sector. With the continent’s EV market projected to grow from $0.45 billion in 2025 to $4.2 billion by 2030 at an impressive annual rate of 56.3%, there’s a clear opportunity for governments to take decisive action.

Supporting Local Manufacturing

Ghana’s policy of an eight-year zero-tariff on EV imports is already attracting global original equipment manufacturers (OEMs) to invest in local assembly. This approach could serve as a model for other nations aiming to build domestic production capacity.

To further encourage local manufacturing, governments should focus on reducing startup costs for manufacturers. Investments in reliable power grids and improved transportation networks are critical to addressing the infrastructure and logistics issues that have long hindered industrial growth.

Another key area is battery component manufacturing. Africa’s wealth of minerals like lithium, cobalt, and nickel – essential for EV batteries – presents a unique advantage. Instead of exporting raw materials, policies should promote local processing and production. Countries such as the Democratic Republic of Congo and Zambia are already exploring this potential through initiatives to establish battery manufacturing hubs.

Additionally, fiscal measures to stabilize currency fluctuations can reduce pricing uncertainties, making it easier for companies to plan long-term investments. These efforts can also pave the way for stronger regional cooperation, helping to integrate supply chains across the continent.

Regional Trade Deals and Supply Chain Development

Regional trade agreements are another critical tool for reducing import dependency. The African Continental Free Trade Area (AfCFTA) offers a framework for creating integrated regional supply chains, enabling African manufacturers to compete with global imports. By standardizing regulations and cutting trade barriers between countries, the agreement allows manufacturers to access larger markets and benefit from economies of scale.

Encouraging manufacturers to source components regionally can further strengthen local supply chains. Harmonizing certification processes across African countries will also help reduce compliance costs and streamline operations.

Collaborative infrastructure projects – such as shared transport corridors and coordinated port facilities – can address logistical bottlenecks and improve the efficiency of regional supply chains. These partnerships between neighboring countries are essential for creating a more interconnected and competitive manufacturing ecosystem.

Government-Business Partnerships and Training Programs

Bridging the skills gap in EV manufacturing requires collaboration between governments, private companies, and educational institutions. Training programs developed with universities, technical schools, and industry partners can equip workers with expertise in EV assembly, battery technology, and maintenance.

Joint apprenticeship programs, co-funded by governments and private companies, can provide direct pathways from education to employment. Moreover, technology transfer agreements with international EV manufacturers, negotiated as part of investment deals, can help workers gain advanced technical skills and accelerate local industry development.

Support for research and development (R&D) is equally important. Governments should back R&D partnerships between universities and private companies to adapt EV technology for African conditions. Co-financed projects can spark local innovation while addressing unique market needs.

Policymakers should also monitor key metrics like local EV production volumes, import/export ratios, manufacturing investments, job creation, and EV adoption rates. Tracking the market share of locally produced versus imported EVs will provide valuable insights into the effectiveness of these policies.

Finally, promoting STEM education and fostering collaboration with international experts can help build a skilled workforce. Initiatives like funding specialized EV engineering programs and facilitating knowledge exchange opportunities can further accelerate the growth of local manufacturing.

Conclusion: Balancing Imports and Local Production

Africa’s electric vehicle (EV) market is projected to grow from $0.45 billion in 2025 to an impressive $4.2 billion by 2030, with a staggering annual growth rate of 56.3%. This growth highlights the importance of finding the right balance between importing EV components and building local production capacity.

Countries like Morocco, South Africa, and Egypt provide great examples of this balanced approach. They combine strong manufacturing capabilities with carefully planned import strategies to meet the needs of both domestic and regional markets. This mix allows for immediate access to EV technology while gradually strengthening local industries.

Policies such as Ghana’s zero-tariff window demonstrate how short-term import measures can complement long-term efforts to develop local manufacturing. These strategies not only encourage EV adoption but also create opportunities to leverage Africa’s rich natural resources.

Africa’s mineral reserves, including cobalt, lithium, and nickel, offer a clear path to becoming a global player in battery production. Countries like the Democratic Republic of Congo and Zambia are already taking steps to shift from exporting raw materials to producing value-added goods like batteries. This transformation could significantly boost the continent’s role in the global EV supply chain.

For Africa to build a thriving EV ecosystem, coordinated efforts across multiple areas are essential. Governments must invest in infrastructure and workforce training, while businesses focus on forming regional partnerships and adopting advanced technologies. The African Continental Free Trade Area provides a platform for creating integrated supply chains, but its success will hinge on consistent policies and active collaboration between the public and private sectors.

In the meantime, platforms like EV24.africa are helping bridge the gap. By facilitating access to imported EVs across 54 African countries, they ensure consumers can start experiencing electric mobility today, even as local production ramps up.

Ultimately, Africa’s EV market will thrive through a carefully timed blend of imports and local manufacturing, setting the stage for a sustainable and competitive future.

FAQs

What challenges does Africa face in building its own EV manufacturing industry?

Africa faces several hurdles in building a local electric vehicle (EV) manufacturing industry. One of the biggest obstacles is the lack of infrastructure. Reliable electricity grids and widespread charging networks are essential for EV production and usage, yet these are often underdeveloped in many regions. On top of that, importing raw materials and advanced technologies for EV manufacturing comes with high costs, making it tough for local industries to compete on a global scale.

Another significant issue is the shortage of skilled labor and technical know-how needed to design and produce EV components. Economic challenges, such as limited access to financing and investment opportunities, further complicate efforts to establish large-scale manufacturing facilities. Overcoming these barriers will require targeted investments, strong government backing, and collaborations with global EV leaders.

How are African countries using their natural resources to reduce dependence on imported EV parts?

Many African nations are working to tap into their wealth of natural resources, such as lithium, cobalt, and nickel – key materials for producing electric vehicle (EV) batteries and components. By focusing on mining, refining, and manufacturing within their borders, these countries aim to build a more self-reliant and sustainable EV supply chain.

That said, there are still hurdles to overcome. Developing the advanced technology, infrastructure, and skilled workforce needed to process these materials locally remains a challenge. While strides are being made, imported EV parts continue to play a significant role in meeting current demand. Platforms like EV24.africa are stepping in to ease this transition by offering buyers across the continent access to a broad range of electric vehicles and related solutions.

How do government policies impact Africa’s EV market and local manufacturing?

Government policies are key to shaping the direction of Africa’s electric vehicle (EV) market and strengthening its local manufacturing potential. Supportive measures like tax breaks, subsidies, or lower import duties can make EVs more accessible and attract investment in local production. In contrast, unclear or restrictive regulations could hinder progress, leaving the region more dependent on imported components.

A stable regulatory framework combined with a focus on infrastructure development can pave the way for innovation and open doors for local industries to grow within the expanding EV market.